Laytrix Ltd, the Darlington headquartered marine solutions provider is delighted to announce the signing of a Memorandum of Understand (MOU) with international subsea business GMC Limited to collaborate on the installation of mechanically connected tendons for the floating offshore wind sector and mechanical connected pipelines for a range of offshore applications.

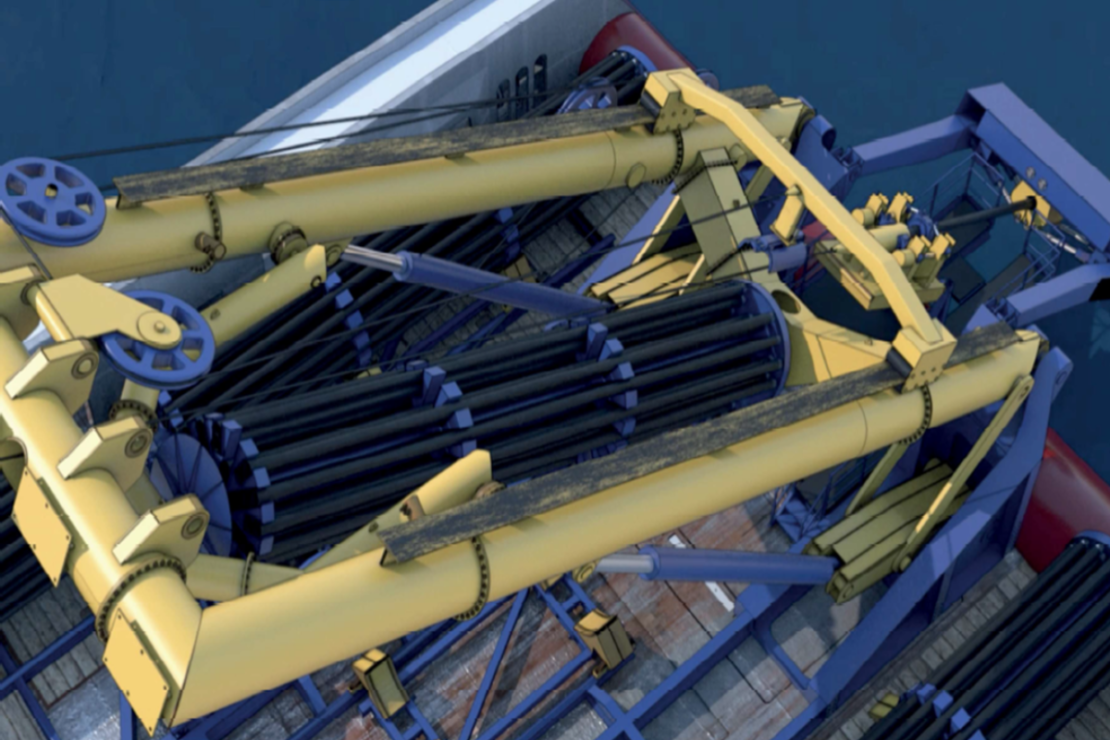

Using the combined proprietary mechanical connection technology of GMC, (which has been qualified in accordance with DNVGL-RP-A203), and the patented installation system of Laytrix, the MOU aims to reduce the costs and improve the efficiencies of constructing pipelines and installing tension legged platform (TLP) systems for floating wind turbine structures.

Andy Stevenson the CEO and Founder of Laytrix advised the companies are already working together as part of a recent Innovate UK funding award which Laytrix received earlier in the year, using the experiences and market knowledge of GMC to help shape the design of its installation system.

GMC Limited CEO Phil Jones added that the two businesses had been aware of each other’s technologies for a number of years, and it was great to finally collaborate in the rapidly growing and exciting floating wind sector as well as the offshore pipeline market where GMC has an established track record.

Laytrix Ltd was established in 2017 as a spin out from an existing design engineering and consultancy business that was providing services to the offshore oil & gas and renewables sectors. The business now has an IP portfolio covering its installation and recovery methods with patents granted in Europe, the Far East and North America and has agents appointed in key markets including South America, Australia, and the Far East. Its decommissioning technology has received multiple industry awards over the last few years.

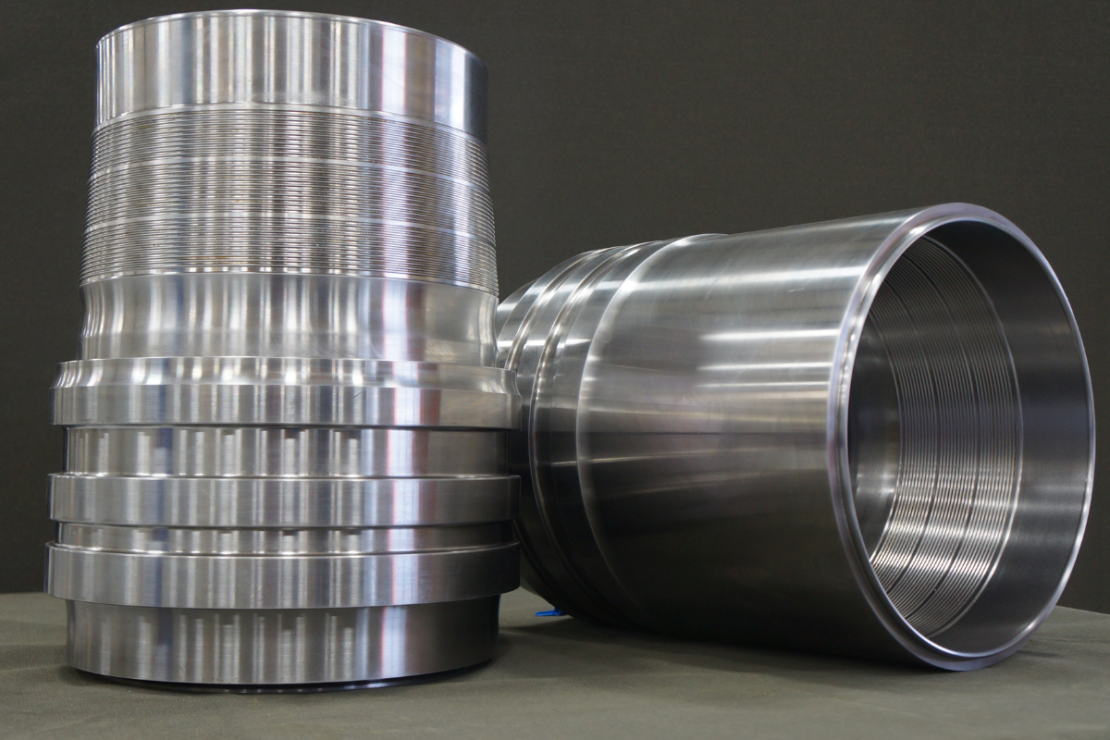

GMC Limited was established in 1990. It is a products, services and engineering company specialising in connected tubular solutions. GMC operates within the oil & gas, renewables and aquaculture sectors. Its mechanical connector systems set a new industry standard for the connection of tubular products. Utilised for multiple applications from a variety of multifunctional vessels, it offers higher fatigue-resistance, faster connectivity, no torquing, and is reusable.